BOLT TORQUE:

Below are the minimum recommended torque values for non-metallic expansion joints with beaded end type flanges to achieve an adequate seal:

SIZES RECOMMENDED TORQUE

1” – 6” 10 ft./lbs.

8” – 12” 20 ft./lbs.

16” – 24” 30 ft./lbs.

NOTE:

Over torquing bolts can cause deformation of the rubber expansion joint flanges, thus resulting in possible

premature failure.

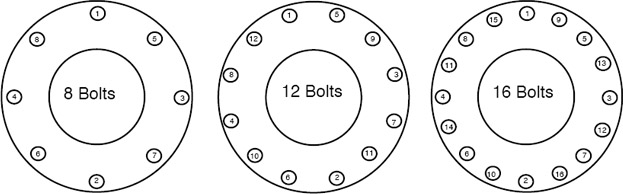

Tighten bolts in stages by alternating around the flange. Use recommended torque values above to achieve a good seal. Never tighten an expansion joint to the point that there is metal-to-metal contact between the expansion joint flange and the mating flange.

STORAGE / HANDLING:

Store expansion joints in a dry/cool location such as a warehouse. Store flange face down on a pallet or wooden platform. Do not store other heavy items on top of expansion joint(s). Ten-year shelf life can be expected with ideal conditions.

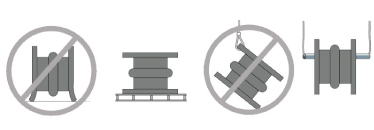

Do not lift with ropes or bars through the bolt holes. If lifting through the bore, use padding or a saddle to distribute the weight. Do not let expansion joints sit vertically on the edges

of the flanges for any period of time.

ADDITIONAL TIPS:

Insulation over a non-metallic rubber expansion joint is not recommended; however, if the insulation is required, it should be made removable to permit easy access to the flange area to check bolting.

It is acceptable (but not necessary) to lubricate the expansion joint flanges with a thin film of graphite dispersed in glycerin or water for ease of disassembly at a later time.

Do not weld in near vicinity of a non-metallic expansion joint.

If an expansion joint is to be installed underground, or will be submerged in water, contact the manufacturer for specific guidelines.

If the expansion joint will be installed outdoors, make sure the cover material will withstand ozone, sunlight, etc. Materials such as Neoprene and Chlorobutyl are recommended. Materials painted with weather resistant paint will provide additional ozone and sunlight protection.

Check the tightness of retaining rings two or three weeks after installation and retighten as necessary.