Flexibility

The flexibility of the VITALFLEX® hose is the result of the bending of the metal corrugations. Service life varies depending upon the severity of the flexing, temperature, corrosive conditions, pressure and vibration to which the hose is subjected.

Unless restrained, corrugated hose will elongate when subjected to increased internal pressure. Restraint is provided by a braided covering, consisting of a tubular sheath of woven metal wires fitted tightly over the corrugated hose and secured at each end. Bending and flexibility of the corrugated hose is not appreciably affected by the wire braid covering.

Tolerances

The nominal length refers to the hose complete with end fittings and indicates the total length. Unless otherwise arranged when ordering, the following length tolerances must be taken into account when checking the nominal length:

| Nominal Lengths | up to 500 | up to 500 | over 500 up to 1000 | over 500 up to 1000 | over 1000 up to 2000 | over 1000 up to 2000 |

|---|---|---|---|---|---|---|

| Tolerances | Min. | Max. | Min. | Max. | Min. | Max. |

| ISO 10380:2012 | 495 | 515 | 990 | 1030 | 1980 | 2060 |

– The ‘‘End to End’’ or ‘‘Seat to Seat’’ length of a hose assembly shall be the length as ordered to a tolerance of +3% / -1

– Smaller length tolerances are possible, but must be specially agreed when ordering.

– Refer to page 330 for hose measurement guide

Braid (ISO 10380)

Unbraided hose (SS0) is satisfactory for vacuum and low pressure applications and for protection against vermin and abrasion.

Stainless steel wire braid (SS1) on the hose assembly provides the hose with a higher internal pressure capability by acting as a restraint against hose elongation, and acts to dampen vibration without significant loss of flexibility.

A second layer of braid (SS2) may be used to increase pressure rating. The test pressure is not to be exceeded or it may incur permanent corrugation deformation.

A third layer of braid (SS3) used to increase pressure rating from SS2.

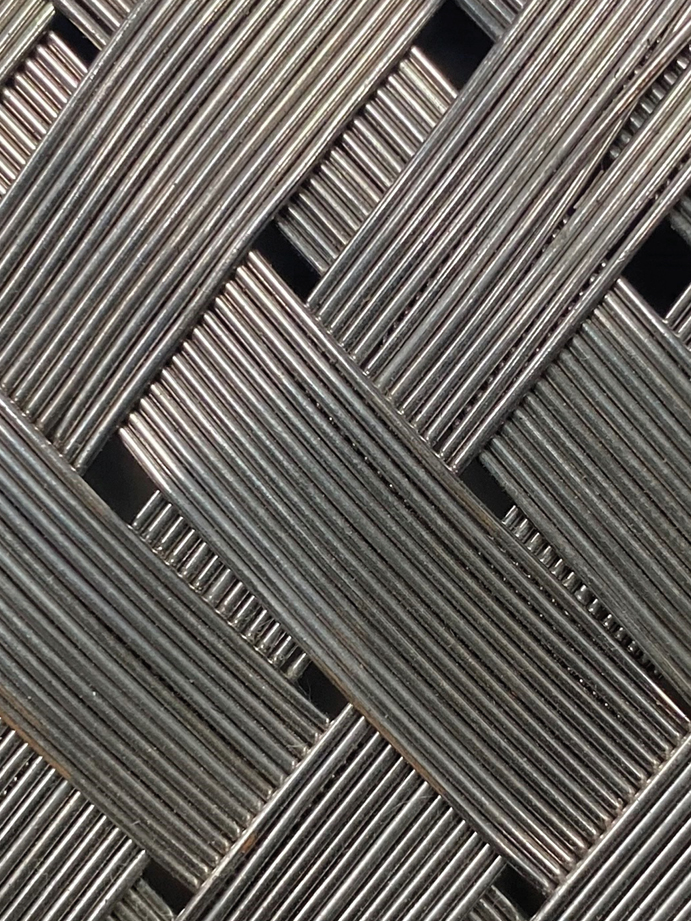

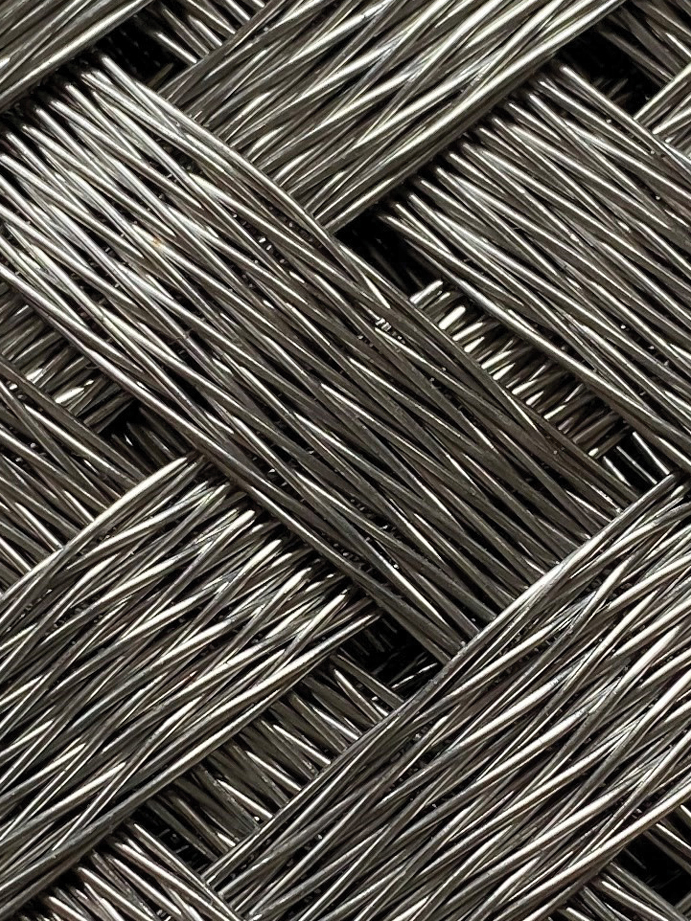

| Annular Braid Style: Open pitch Material: 316 and 304 Pressure: Medium |

Omega Braid Style: Close Pitch Material: 316 and 304 Pressure: Medium |

Braided Braid Style: Open Pitch Material: 316 and 304 Pressure: High |

|

|

|

Flow Velocity Consideration

The flow velocity in corrugated metal hose should never exceed 150 ft/sec for gas, or 75 ft/sec for liquids. When the hose is installed in a bent condition, these flow values should be reduced proportionally to the degree of the bend. Where the flow velocity exceeds these rates, an interlocked metal hose liner is recommended. Refer to Nomograph

Service Life

The Stainless steel corrugated hose is engineered to provide maximum service life when properly installed. Incorrect installation, incorrect flexing or careless handling in an application will reduce the effective service life of the hose and cause premature failure of an assembly. The service life can be affected by many external factors, the environment surrounding the assembly as well as the media being transferred will together determine a general guide to the service life.

Non Destructive Pressure Testing

The nominal pressure rating of a corrugated stainless hose varies according to type, material and size. The pressure can be affected by factors such as temperature, pulsation or shock conditions and bending stresses. To avoid distortion of the convolutions of the hose, the maximum test pressure quoted in the literature must not be exceeded. If requested all hoses can be tested to 11⁄2 times the customers stated working pressure, provided that this does not exceed the stated maximum test pressure.

Applicable Standards

If required your hoses can be manufactured for use with gas and water.

– ISO 10380:2012

– ISO 9001:2008

– AS 2475 Threaded Hose Connection Fittings for Bituminous Materials

– AGA Approved: AS 4631:2005 (upon requirement)

– Watermark Approved (upon requirement)

– Welding Compliant to: AS 4041

– Class 1 (upon requirement)